FIBRPRO® SYNTHETEC® FRP REINFORCED STONE AND ITS APPLICATION

H.T. WONG1,2* 1Fibrpro Holding Limited, Hong Kong, China2Fibrpro New Material Technology (Shenzhen) Limited, Shenzhen, ChinaEmail: wting@fibrpro.com

*Corresponding Author

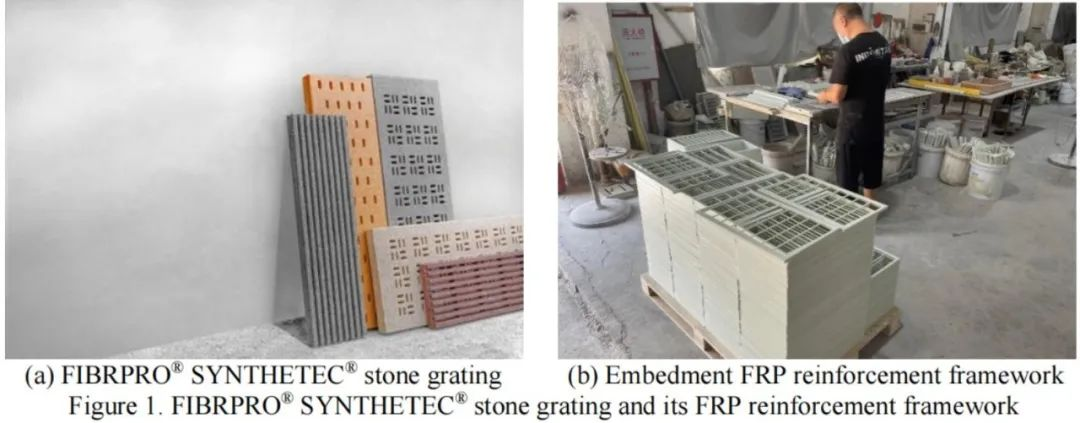

ABSTRACTFIBRPRO® SYNTHETEC® FRP Reinforced Stone Grating (hereafter referred as “Grating”) a revolutionary precast solution, merges proprietary SYNTHETEC® synthetic material with fibre reinforced polymer (FRP) rebars. The Grating offers limitless color choices, customizable sizes, and incorporates sustainability with its anti-slip, micro-holes surface, and site-cuttable features for barrier free access and ease of installation. The only limitation is the imagination. The Hong Kong R&D proprietary Gratings are manufactured in FIBRPRO’s self-owned manufacturing facilities in Guangdong Province of Chinese Mainland. Nowadays, the Grating has gained widespread approval and adoption across various sectors in Hong Kong, and has successfully expanded its footprint to international markets, including Singapore, Macau, and the Middle East KEYWORDS

FRP, reinforced stone, proprietary new material, non-metallic, sustainability, international applications.

INTRODUCTION

SYNTHETEC® and SYNTHETEC® Grating

FIBRPRO® SYNTHETEC® FRP Reinforced Stone Grating (hereafter referred as “Grating”), a testament to innovation, is crafted from our proprietary SYNTHETEC®, developed through rigorous domestic R&D. The synthetic material integrates low content (about 15% by weight) of resin / polymer material, such as polyester, epoxy methacrylates, phenolics, furans, vinylester etc. and binder such as quartz sand, natural or recycled crushed stone and recycled filler such as fine aggregate, mineral granulation or reused fibers. The grating not only meets but exceeds the demands of modern construction with its versatility in design, durability, and sustainability, it is also reinforced by FRP rebars when the load-bearing is a necessary design feature.

The mixed compound with designated color achieved with an agglomeration of natural stone substrates and mineral oxides is filled into moulds and compacted to form panels to any shapes and architectural features through an advanced state of the art vacuum and compression process. The manufacturing process does not require any heat, thus it produces fewer carbon emissions compared to traditional iron, steel and composite gratings.

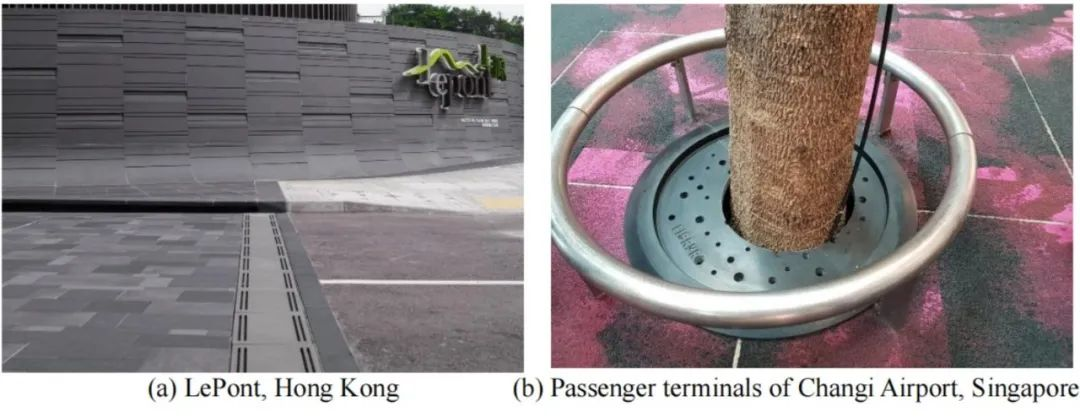

The Gratings are manufactured in FIBRPRO®’s self-operated manufacturing facilities in Guangdong Province of Chinese Mainland. Nowadays, the Hong Kong R&D proprietary SYNTHETEC® Gratings have been widely approved and adopted by government departments (i.e. ASD, EMSD, HyD, DSD, CEDD, LCSD, Housing Authority, Hospital Authority), public service organizations (i.e., HKU, HKBU, MTRC, Science Park, Ocean Park, AsiaWorld Expo, Airport Authority, Po Leung Kuk, LINK, various primary and middle schools) and developers (i.e. Vanke, Wing Tai, China Overseas) in Hong Kong. The Grating has also made significant inroads is overseas, with notable installations at the state-of-the art Changi Airport and the prestigious MGM Cotai. These deployments underscore the product’s ability to meet the rigorous demands of high-profile international projects. With the employment of local agents, markets of Chinese mainland and oversea are under exploring.

SYNTHETEC® IS THE LANDSCAPE

SYNTHETEC® is a proprietary synthetic stone material solely invented by a domestic Hong Kong research and development team of FIBRPRO®. The journey of creating this strong, durable, aesthetically appealing, environmentally friendly and multi-functional matching artificial stone started in 2010, inspired by the beautiful and magnificent Romanesque Architecture with its widely use of granite, marble, terrazzo.

With the growing demand for matching artificial stone products and features across the construction industry, FIBRPRO® established in 2020, after 10 years of development, our proprietary range of artificial stone products labelled as “SYNTHETEC®”. This was achieved with much collaboration with many property developers, architects, engineers and distinguished customers. Comparing with the CORIAN®stone of DUPONT®which is focusing mainly to the interior features, FIBRPRO® SYNTHETEC® dedicates to deliver the best functional STONE solutions to the indoor and outdoor design creations for public.

In July 2020, The Grating and Tree Pit Cover, as innovation technology / products, are certified to be included in the pre-approved list of the Construction Innovation and Technology Fund (CITF) in considering the outstanding performance in accordance with factors of boosting productivity, uplifting built quality, enhancing environmental performance and improving site safety.

SUSTAINABILITY OF SYNTHETEC®The FIBRPRO® team is committed to embedding sustainability across every project interface. SYNTHETEC® embodies eco-friendliness, with at least 20% recycled materials in its composition and a manufacturing process that forgoes heating, significantly reducing carbon emissions compared to traditional methods, and other material involving traditional iron and steel industries.

ADVANTAGES OF THE GRATING

The Grating offers an extensive color palette, enabling seamless integration with any architectural design. Its durability, sustainability, and load-bearing capabilities make it an ideal choice for both standard and customized applications, with anti-slip and micro-holes surfaces enhancing safety and accessibility. limitless color choices. The only limitation is the imagination.

Uplifts Built Quality

The fully non-metallic material of the Grating prevents rust and corrosion mean they are equally suited to last a lifetime for both indoor and outdoor applications. Further, full range colors to RAL chart are available for selection provides architect almost limitless possibilities for matching with the environment. Furthermore, the usage of stone grating enhances the value of properties because of the premium look and finish it provides as an alternative to iron and steel gratings.

Improves Safety

The Grating has a natural slip resistance because of the textured finishing post-production process, and it is an essential merit for places where water is prevalent. Secondly, Grating can have slim 6mm slots and small radius fillets to prevent high heels from being caught in the grates. It is compliant with Barrier Free Access (BFA) by Buildings Department of Hong Kong and Americans with Disabilities Act (ADA) requirements, these are extremely useful for cut-off or scupper drains of the entrance or concourse areas of a building. Thirdly, the self-weight of the Grating per piece is much lighter than the transitional iron and steel ones at the same size and volume, which enhance the occupational safety & health at maintenance. Fourthly, stone Grating absorbs much less heat from the sun than traditional ferrous gratings, making it a more comfortable material to have around the house and in children’s playgrounds.

Last but not the least, stone Grating has no scrap value and is thus safe from theft. This prevents a sudden void at the street or road which causing injury issue.

Enhances Environmental Performance

The Grating can incorporate upto 30% recycled content in the raw material, and the manufacturing process does not require heating, thus it produces fewer carbon emissions compared to traditional iron and steel industries; Further, the placement and installation of the synthetic grating generally requires neither plant nor equipment, therefore it consumes no fuel during the construction process. Furthermore, the manufacturing facility of the Grating locates at Huizhou of Guangdong Province, a city within 100 km to Hong Kong, thus it generates less carbon footprint during the transportation of the grating comparing imported the similar from overseas.

Boosts Productivity During the Construction Process

It is a precast and prefabrication unit, ready for placing in-situ for completing the installation when delivered to site. Moreover, the self-weight of the grating per piece is much lighter than the traditional iron or one at the same size and volume, so it speeds up the placement and installation.

FUTURE DEVELOPMENT

To further develop the SYNTHETEC®, a research and development project, undertaken by FIBRPRO® team and supported and sponsored by the Enterprise Support Scheme (ESS) (Project Reference:S/E024/21), is commenced since July 2022. The ESS is under the Innovation and Technology Fund (“ITF”) and set up by the Government of The Hong Special Administrative Region as represented by the Commissioner for Innovation and Technology. The project is to develop an innovative cement-based material (the new material) to replace the organic polymer-based material and minimize the environmental impact. The new material is volatile organic compounds (VOC) free and has a compressive strength about 150 MPa, which is approximately two times that of the material in using. It will upgrade the products with enhanced load carrying capacity, and form the foundation for the next investigation to set up the manufacturing facilities in other regions, for example Hong Kong, which is enforcing more critical environmental protection restrictions and schemes but welcome the re-industrialization. FIBRPRO® is also exploring the possibility to set up production facilities in Hong Kong to manufacturing the grating, and if successes it will further reduce the carbon footprint for the whole process in long term.

CONCLUSIONS

The FIBRPRO® SYNTHETEC® FRP reinforced stone grating stands as a beacon of innovation in the construction industry, offering a sustainable, customizable, and high-performance solution that has gained global recognition and is poised for further expansion. It is a precast unit fabricated from the proprietary and domestic research and develop (R & D) synthetic material of SYNTHETEC® and reinforced by fibre-reinforced polymer (FRP) rebars. The Grating offers limitless color choices. Nowadays, the Grating has gained widespread approval and adopted by various projects of Hong Kong and overseas.

ACKNOWLEDGEMENTS

The author gratefully acknowledges the financial support provided by the Enterprise Support Scheme (ESS) (Sub-Fund No.: S/E024/21) and Research Talent Hub ((Sub-Fund No.: RtH/001/21RP, RtH/002/21PH, RtH/053/21RP under the Innovation and Technology Fund (“ITF”) and set up by the Government of The Hong Special Administrative Region (“HKSAR”).

REFERENCES

Fibrpro International Limited website, www.fibrpro.com

Synthetec Stone Grating website, en.fibrpro.com

Please follow the Wechat official account:

Fibrpro New Materials Technology (Shenzhen) Limited.